PET+PTFE+Flame retardant+Antistatic Filter Cartridge

1. A non woven fabric that can be folded is synthesized by adding carbon powder or metal conductive wire to the basic material of PET. The filter cartridge is installed with conductive copper braided tape, which can remove static electricity after grounding.

2.For example, in the production process of plastic particles, plastic fine dust is prone to generate static electricity and adsorb on the filter cloth. Pulse cleaning is not easy to remove the dust. In this case, anti-static material filter cloth needsto be selected for this working condition.

3. For example, the metal powder of flammable and explosive aluminum magnesium titanium alloy is prone to flammable and explosive accidents. At this time, it is necessary to eliminate static electricity and ground it through the copper braided belt of thefilter cartridge to remove static electricity and prevent fire and explosion accidents.

4. Polyester filter cartridges have certain acid and alkali corrosion resistance, and can operate normally in harsh environments such as acidic and alkaline conditions, without being easily corroded by chemicals.

1.1.For example, in the production process of plastic particles, plastic fine dust is prone to generate static electricity and adsorb on the filter cloth. Pulse cleaning is not easy to remove the dust. In this case, anti-static material filter cloth needs to be selected for this working condition.

1.2.For example, the metal powder of flammable and explosive aluminum magnesium titanium alloy is prone to flammable and explosive accidents. At this time, it is necessary to eliminate static electricity and ground it through the copper braided belt of the filter cartridge to remove static electricity and prevent fire and explosion accidents.

1.3.The usual weight is 240 grams per square meter, 260 grams per square meter, and 300 grams per square meter.

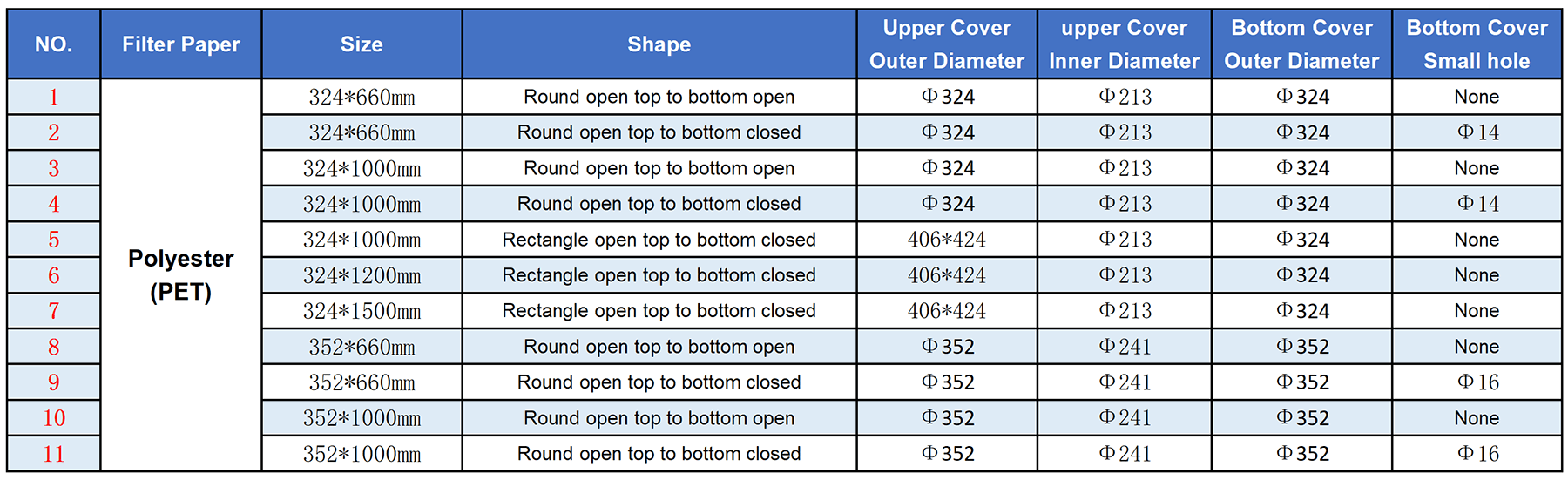

1.4.In fact, the length of the filter cartridge can be customized non-standard within 0-3 meters, and the shape of the filter cartridge cover can also be customized non-standard according to your sample.

1.1、 Art.No.EHFIL001

1.2、 Art.No.EHFIL002

1.3、 Art.No.EHFIL003

1.4、 Art.No.EHFIL004

1.5、 Art.No.EHFIL005

1.6、 Art.No.EHFIL006

1.7、 Art.No.EHFIL007

1.8、 Art.No.EHFIL008

1.9、 Art.No.EHFIL009

1.10、 Art.No.EHFIL010

1.11、 Art.No.EHFIL011

1.12、 Art.No.EHFIL012

1.13、 Art.No.EHFIL013

1.14、 Art.No.EHFIL014

1.15、 Art.No.EHFIL015

1.16、 Art.No.EHFIL016

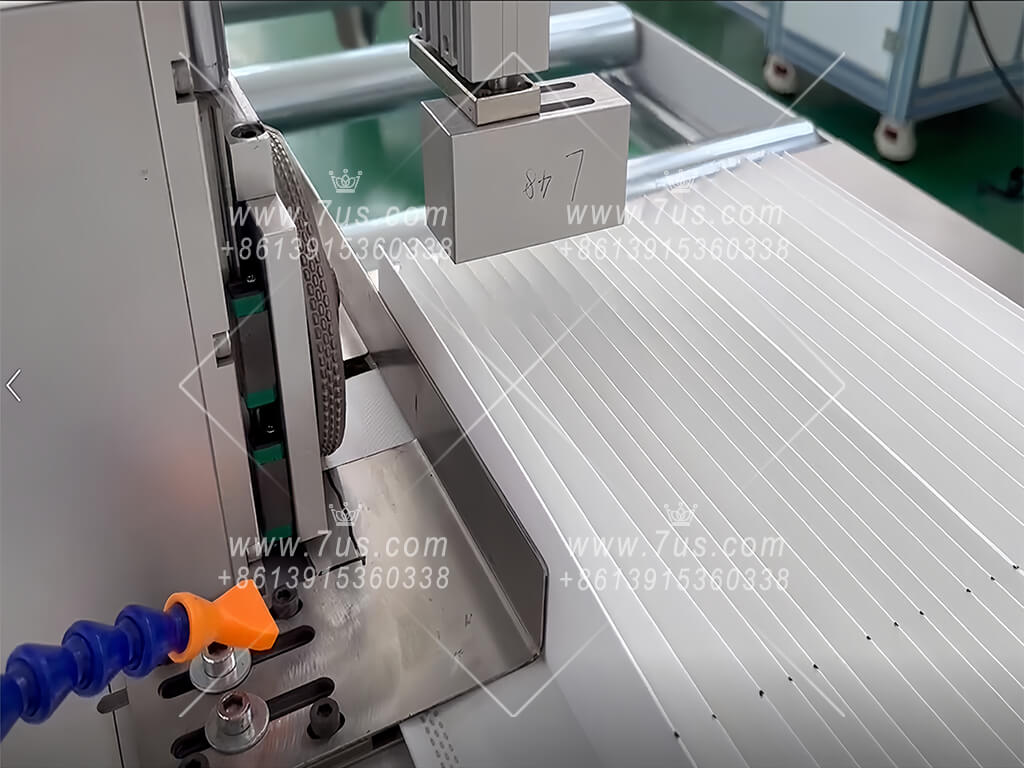

PET Paper Pleating Machine

PET Paper Pleating Machine

Cellulose Paper Pleating Machine

Cellulose Paper Pleating Machine

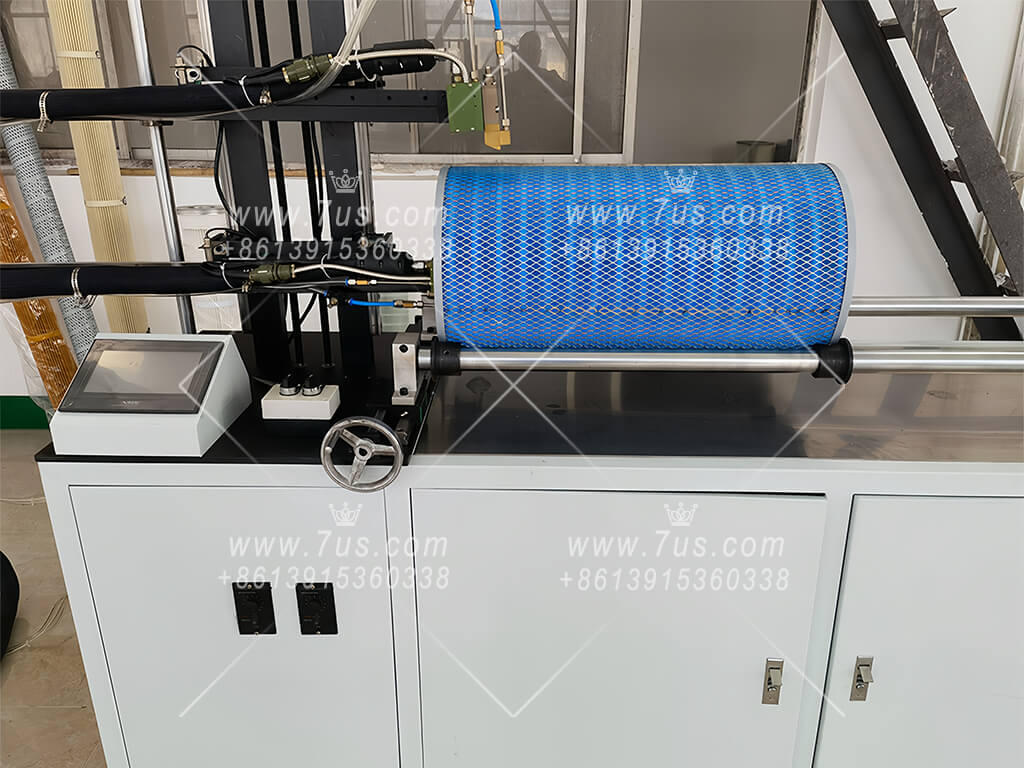

Automatic Spiral Gluing Machine

Automatic Spiral Gluing Machine

Automatic Production Line For Porous And Diamond Mesh Skeleton

Automatic Production Line For Porous And Diamond Mesh Skeleton

3-meter-long Filter Paper Pleating Machine

3-meter-long Filter Paper Pleating Machine

Ultrasonic Welding Of Filter Paper Seam

Ultrasonic Welding Of Filter Paper Seam

Ultrasonic Welding Of Filter Paper Binding Tape

Ultrasonic Welding Of Filter Paper Binding Tape

Strap Tail Ultrasonic Welding

Strap Tail Ultrasonic Welding

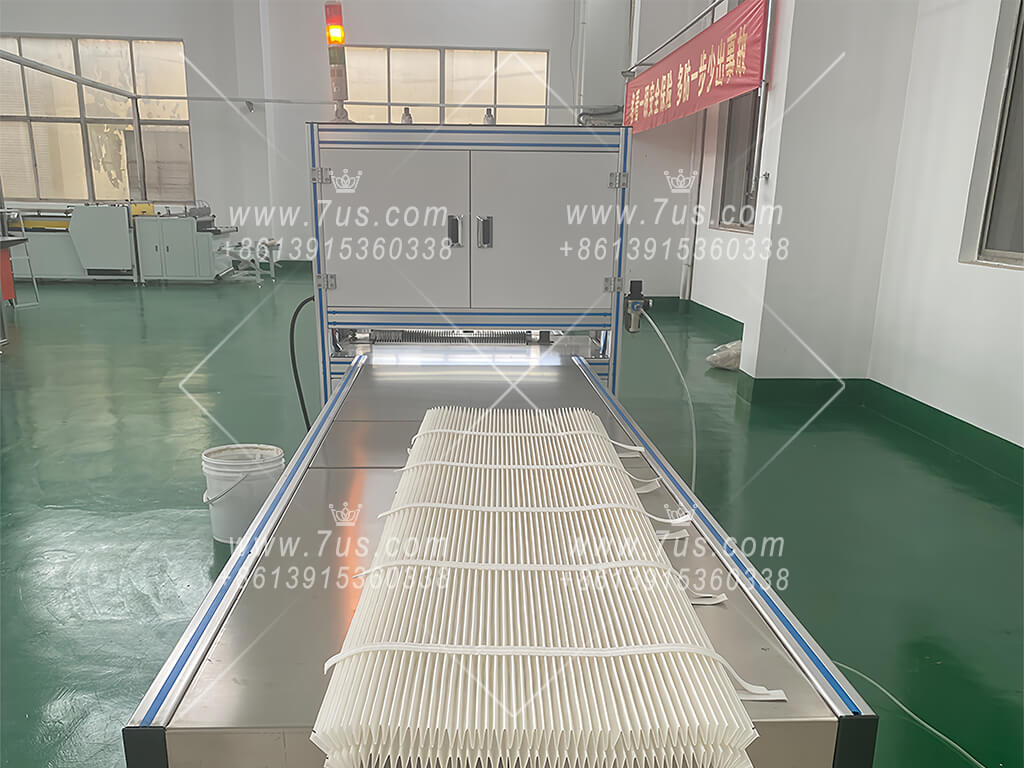

Cellulose Paper Filter Cartridge Production Site

Cellulose Paper Filter Cartridge Production Site

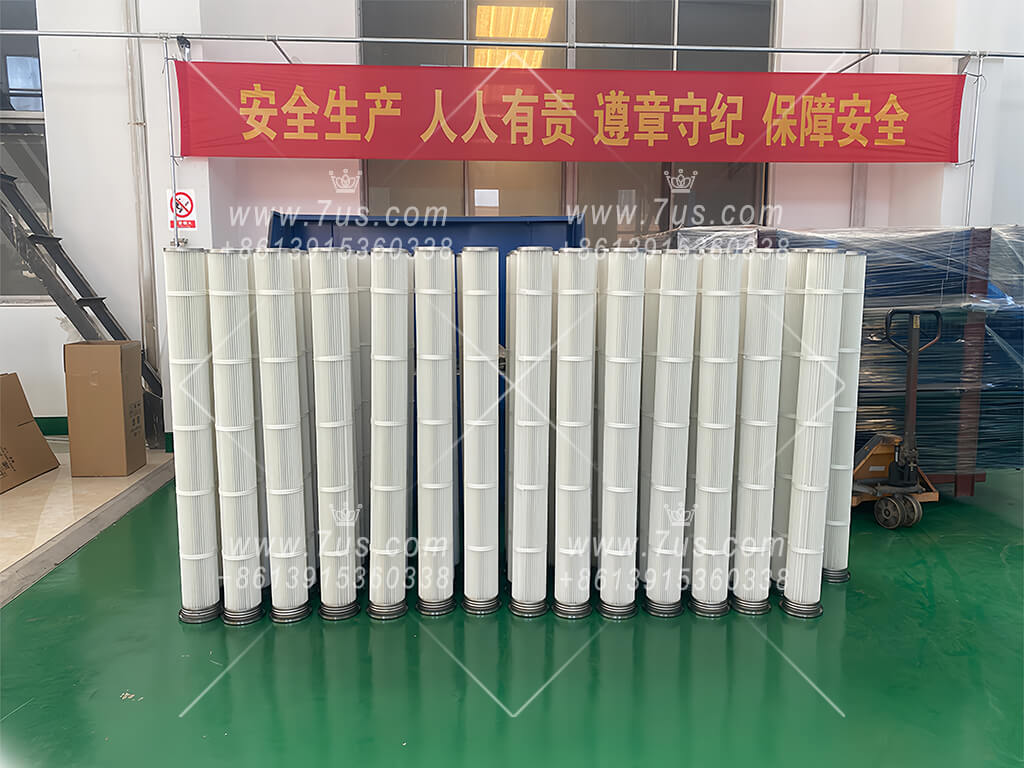

PET Paper Filter Cartridge Production Site

PET Paper Filter Cartridge Production Site

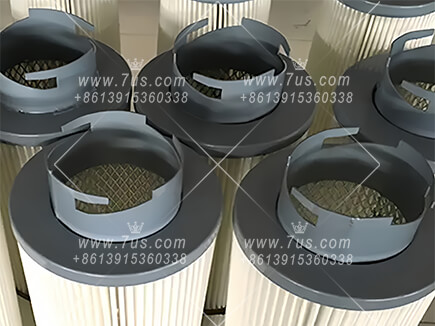

Square Lid Chuck Filter Cartridge Production Site

Square Lid Chuck Filter Cartridge Production Site

Fine Filter Cartridge Instead Of Bag

Fine Filter Cartridge Instead Of Bag

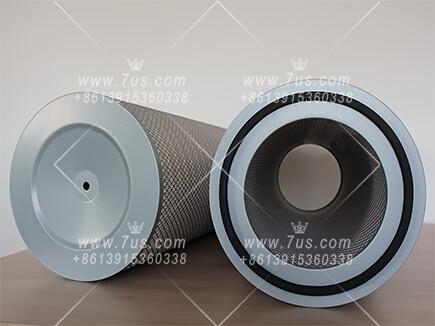

The filter cartridge, also known as the filter element, is the heart of a dust collector and is a filtering element used to separate smoke and dirty air, thereby obtaining clean air. It belongs to consumables. Air filters are actually a type of dust collector, such as self-cleaning air filters, commonly used as pre filtration devices at the air inlet of gas turbines, high-temperature fans, and air compressor stations.

1.2: Is the filter cartridge better than bag?Compared to cloth bags, filter cartridges have a larger filtration area when using wrinkled filter paper at the same volume. When encountering high concentration dust, a cyclone dust collector is needed for pretreatment, and then a filter cartridge dust collector is used. Replacing bags with drums, increasing filtration area, reducing filtration wind speed, improving purification capacity, and energy conservation and emission reduction have become trends. For example, in the current popular steel industry, using 3-meter-long filter drums to replace cloth bags has become a trend, and emission concentrations can reach below 10 milligrams per cubic meter.

The filter cartridge usually uses compressed air with a weight of over 4 kilograms to blow back, causing the filter paper to expand and vibrate. Dust falls off and separates from the surface of the filter paper, reducing resistance, and thus obtaining pulse valve injection compressed air for ash cleaning and regeneration.

1.4:What are the dimensions of the filter cartridge?The size of filter cartridges usually includes 350 * 660mm, 324 * 660mm, 324 * 1000mm, and various sizes that replace cloth bags. The width of filter paper can reach 3000mm, which means that filter cartridges within a length of 3 meters can be customized.

Filters usually come in round filter cartridges, conical filter cartridges, and fine filter cartridges. For all shapes of filter cartridges on the market, we can replicate and replace them according to your sample requirements.

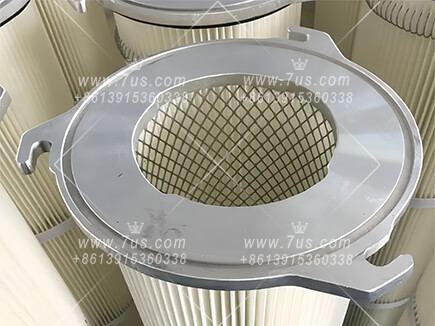

1.6: What are the installation methods for filter cartridges?The installation methods of filter cartridges include flat installation, oblique insertion, chuck pressure rod type, nut lifting type, three ear screw in type, top installation type, bottom installation type, side installation type, and so on.

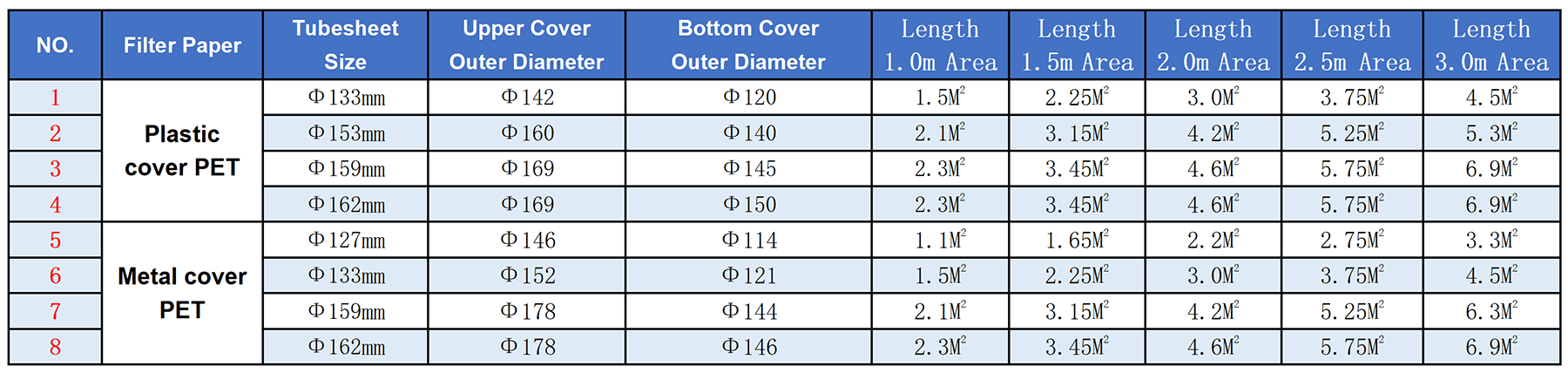

In terms of basic materials, the main substrates for filter cartridges are fiber paper and polyester (PET). Of course, there are also high-temperature resistant composite wrinkled non-woven substrates such as glass fiber, PPS, P84, NOMEX, etc.

2.2: What is a paper filter cartridge?Using fiber paper as the basic material, abbreviated as substrate, is usually used to filter low concentration flue gas. For filter cartridges of the same size and specification, fiber paper has more wrinkles. Taking a 350 * 660mm filter cartridge as an example, the filtering area is usually around 20-23.4 square meters.

2.3: What are the functional options for paper filter cartridges?

On the substrate of fiber paper, surface treatment with functions such as nanocoating, flame retardancy, and anti-static can usually be carried out, followed by deep processing and comprehensive composite technology.

Using polyester (PET) wrinkled non-woven fabric as the substrate, it is usually used for relatively high concentrations of dust. Filter cartridges of the same size and specification have more polyester wrinkles. Taking a 350 * 660mm filter cartridge as an example, the filtration area is around 9-10 square meters.

2.5: What are the functional options for polyester filter cartridges?

On the substrate of polyester, surface treatment with functions such as lamination, flame retardancy, and anti-static can usually be carried out, followed by deep processing and comprehensive composite technology.

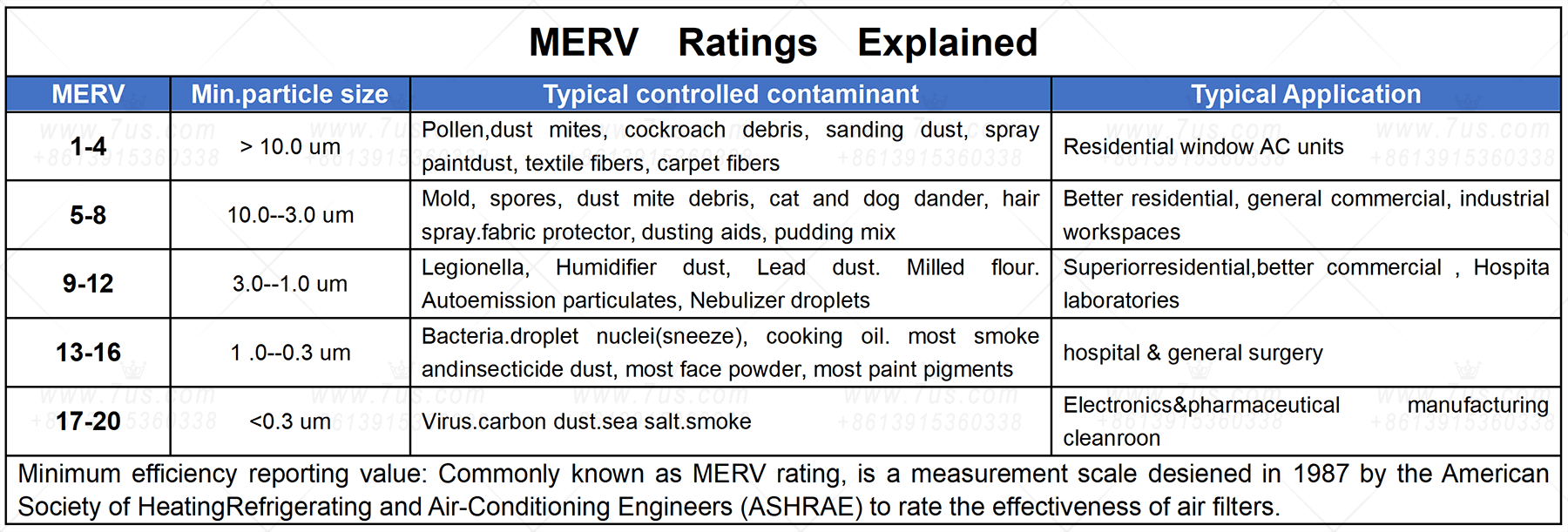

3.1: How is the accuracy of the filter cartridge ensured?

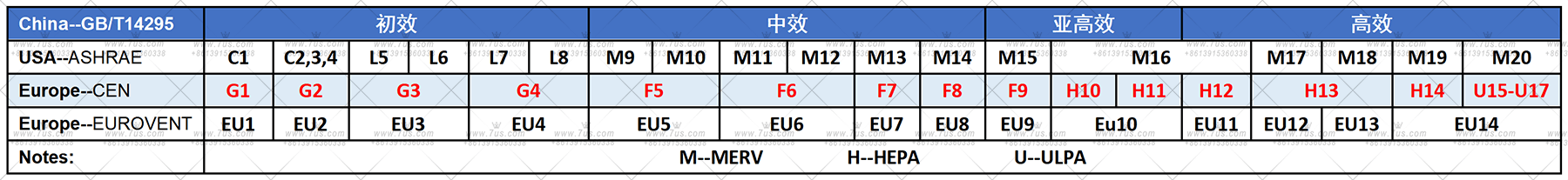

The accuracy of the filter cartridge is mainly achieved through surface treatment of the substrate. The microporous membrane composite on the surface of the substrate has a smaller microporous diameter, higher efficiency, and a higher relative resistance. The efficiency of wood pulp paper substrate is around F5-F7 level, and after nanofilm composite, the efficiency is between F9-H10 level. The substrate efficiency of polyester filter material is around F5-F9 level, and the efficiency after PTFE coating can reach purification levels of H10-H12 level. The weight of wood pulp paper is usually 135 grams per square meter, the weight of polyester non-woven filter paper is usually 240 and 260 grams per square meter, and the weight of high-temperature PPS, P84, NOMEX filter paper is usually 360 grams per square meter. Similar to the logic of bag material, it has a significant weight, high precision, and high price.

3.2: What is the difference between nano, adhesive film, and thermal film?Nano coating technology, also known as nano coating technology, is usually aimed at paper filter cartridges made of wood pulp paper substrate. Immersion and non immersion are mainly aimed at polyester substrates. The filter paper after immersion is relatively firm and aesthetically pleasing when folded and formed. The filter paper soaked in glue can usually only be coated with glue. Instead of impregnating polyester substrates, thermal lamination, PTFE or EPTFE thermal lamination, which is currently an advanced lamination process, is commonly used.

3.3: The larger the filtration area of the filter cartridge, the higher its filtration efficiency?In theory, this is the case, but blindly increasing the filtering area is not feasible because the larger the area, the more relative wrinkles, the tighter the spacing, and the easier it is to trap dust, which is not conducive to dry cleaning and has a shorter service life.

3.4: What is the appropriate filtration rate for the filter cartridge?In theory, the slower the filtration speed, the higher the filtration accuracy. However, as the corresponding area increases, more filter materials will be used, and the dust collector box equipment will also become larger, resulting in an overall increase in comprehensive costs. Considering both filtration accuracy and investment cost, a reasonable wind speed is usually chosen. The filtration speed range of paper filter cartridges is usually 0.5-0.7 meters per minute, while the filtration speed range of polyester filter cartridges is usually not more than 1.2 meters per minute.

Phone